Discussion Forums

Forum Index

> Equipment

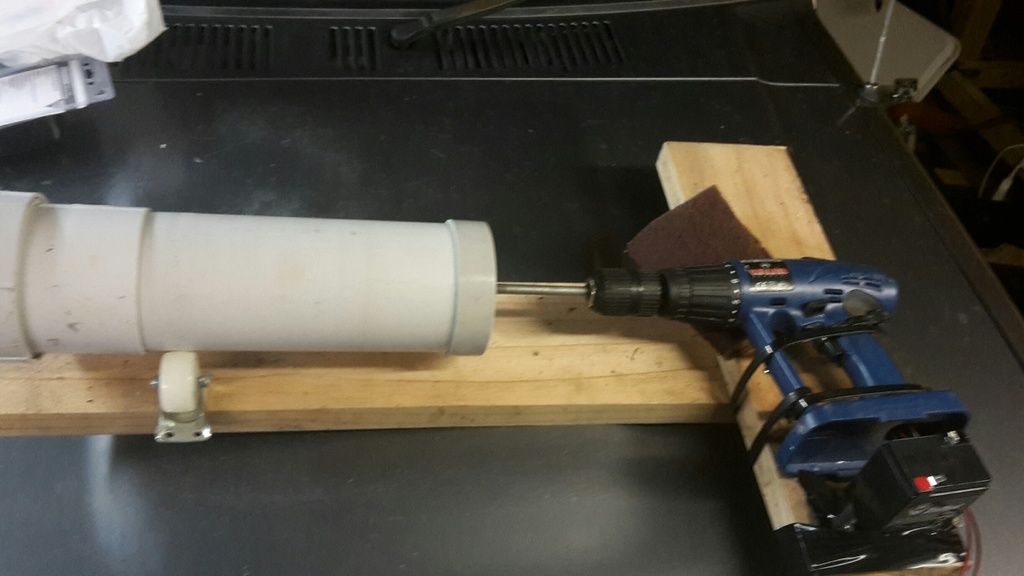

> home made tumbler

home made tumbler

Replies

|

@ 08:43 pm (GMT) |

Bob MavinRe: home made tumblerLooks like your using the good caliber too Thomas :) |

|

@ 10:52 pm (GMT) |

|

|

@ 12:29 am (GMT) |

Paul LevermanRe: home made tumblerThomas, it's your thread. But I think we should see what every body else has come up with as well. Are you good with that?Nice job on the tumbler. I really don't like cleaning brass, but the tumbler takes forever, and I can do a bunch of brass in an hour. But I really don't like cleaning brass, but I don't like waiting even more. |

|

@ 12:37 am (GMT) |

Bob MavinRe: home made tumblerStick it in the tumbler.... crack a bottle ;-)Then do it tomorrow |

|

@ 01:25 am (GMT) |

Thomas KitchenRe: home made tumblerGo for it Paul I'm interested just as much as the next guy to see what people have come up with.I'm with Bob on that one, tumble brass at least a day before you plan on reloading it. got to love the 270win eh Bob. |

|

@ 01:55 am (GMT) |

Warwick MarflittRe: home made tumblerGet some miniature stainless steel punchings or small chip swarf put in a wee squirt of car polish and in a short time it's clean. I have ground walnut shells it does a great job but takes around 2 hours. I made mine from a 2 litre bucket that I put in lathe chuck in lowest gear. It works great. You could use a 12 volt wiper motor from a car. They are two speed and have a built in reduction. Well done Thomas. |

|

@ 08:09 pm (GMT) |

Chris MurphyRe: home made tumblerNice Thomas I'm in the process of whizzing one up using a motor and reduction box out of a car electric window. Good to see kiwi ingenuity still kicking |

|

@ 05:06 am (GMT) |

Andrew MurrayRe: home made tumblerI know some bench grinders that you can gear down to very slow speeds. I'm into straight shaving and a guy I use for repairs has one. I think it's at something like 60rpm or even less. He runs a water wheel set up to keep the temperature down, plus steel that thin and tempered gets rather fragmented when you grind it to fast/hot. I know from experience.Having said all that, I'm not sure of the brand or set up he is using. |

|

@ 03:56 pm (GMT) |

Paul LevermanRe: home made tumblerI tried annealing the SST's as per the video and tutorials, but it just wasn't working. Not the annealing part, the gripping and turning of the pliers. I could not get the bullets to heat evenly as it was just too awkward (my wrists and arms are buggered). I gave up for a long time. While I was setting up my 308 for reloading, a flash of mediocrity hit me. I have a cartridge case for every caliber that I shoot that has the neck split for getting the COL. I stuck an SST into it and that cured the spinning problem. Now I can just roll the bullet in the flame by spinning the case in my fingers.As well, my grip on the forend (Hold that forend!) is sadly lacking. If I use the overhand method it's ok, but I can't grip the stock itself properly. Hence another alternative was needed. I used a wax toilet seal (a new one, Thomas) and moulded it into ball. Then I gripped it and just started squeezing until it was formed to a point that was a neutral grip shape. After a little trimming here and there, I put it into a 2 litre milk carton and poured in enough plaster to cover it. After it had set, I melted the wax out and used the mould to form a castable urethane hand grip. With a 1/4-20 stud in the top, it threads right into the swivel stud on the stock. Now I have a vertical, custom hand grip and that forend is not going anywhere. (There's way more to the moulding process, but I shortened it for here. If you want the details, I will gladly post them.) |

|

@ 08:06 pm (GMT) |

Andrew MurrayRe: home made tumblerThat's tops Paul, way to think outside the box. |

|

@ 05:17 am (GMT) |

Bryan WebsterRe: home made tumblerI have several Lee case holders for different calibers, they are for trimming cases to lenght, and when I need to anneal brass I just chuck the case holder into a electric screw driver with a very slow rotation option and use that in a propane torch flame. Works very well, and beats the heck out of unsteady handling with a set of pliers to hold onto the case.Before doing this I put a bit of 650 defree Tempaq inside the neck, turn the lights down and time how long it takes for the Templaq to melt, then use the number of seconds that took for the rest of the brass. I annealed some 180 grain Hornday SST bullets the same way, but puting it in a case in which I had sliced a vertical hole so the neck tension was light. Chucked it into my case holder and used the candle flame for the heat. Very steady, worked well and performs well too. |

|

@ 02:41 pm (GMT) |

mark korteRe: home made tumblerJust saw this - thats one sick tumbler Thomas! |

|

@ 12:14 pm (GMT) |

Paul LevermanRe: home made tumblerI found yet another use for the split neck case.Using your calibre of choice, take the longest bullet you have (preferably with a cannelure and a boattail). Put it in the chuck of your cordless screwdriver, tip facing in. With a file, some sandpaper, and a maroon pad, reduce the diameter of the bullet until it just slips into a sized case. You don't want it tight, but try not to take too much off so it wobbles. Once it's machined down in size, put it into the split neck case backwards and put the case into your bench vise (my vise has 1/4" cork glued to the jaws, you can wrap your case in a rag or anything else that will protect it. It doesn't have to be super tight, just enough to keep it from moving from finger pressure.) Set up your dial indicator so that the plunger is zeroed on the bullet. Take a sized case, dip it into some graphite powder, run it onto the bullet, spin your case slowly and carefully and watch the dial. You now have a very cheap tubing micrometer to measure your neck thickness. With a little practice, it takes very little time to check your cases. I've found that the trick is to use a delicate touch. It also helps if your split case and your sized cases have been trimmed square, then you can just butt them up to each other. I've not compared this to a real tubing micrometer, but it is way more accurate than verniers. If you have a tubing micrometer and you want to make a comparison, that would be greatly appreciated. |

|

@ 06:01 pm (GMT) |

Paul LevermanRe: home made tumblerAnother homemade tool: kinetic bullet puller.The casings I use are too big for the commercial hammer type pullers. Ruining ELD-Ms and A-MAXs with pliers got real old real fast. This is what I made. Take a 1/2"NPT brass Tee, add a 6" 1/2"NPT nipple and a 12" 1/2"NPT plastic pipe, and a 1/2"NPT cap. https://imgur.com/a/Yatqq Use the Tee fitting as a mold and add Match Grade Bedding compound to fill around the cartridge case. Let set and remove cartridge. https://imgur.com/a/Yatqq Other end. https://imgur.com/a/Yatqq Insert the case into the tool, add the brass pipe and cap to catch everything, install the plastic pipe as the "hammer" handle. https://imgur.com/a/Yatqq Give it a couple of good whacks and you're done. Bullet and brass separate, ready for reassignment. |

|

@ 06:02 pm (GMT) |

Paul LevermanRe: home made tumblerWell that didn't work. Why am I not surprised.I could screw up The Lord's Prayer, if I knew it. I put the images out to the public, maybe that will work. |

|

@ 06:15 pm (GMT) |

|

|

@ 03:57 pm (GMT) |

Paul LevermanRe: home made tumblerQuote: Another homemade tool: kinetic bullet puller.

The casings I use are too big for the commercial hammer type pullers. Ruining ELD-Ms and A-MAXs with pliers got real old real fast. This is what I made. Take a 1/2"NPT brass Tee, add a 6" 1/2"NPT nipple and a 12" 1/2"NPT plastic pipe, and a 1/2"NPT cap.

Use the Tee fitting as a mold and add Match Grade Bedding compound to fill around the cartridge case. Let set and remove cartridge.

Other end.

Insert the case into the tool, add the brass pipe and cap to catch everything, install the plastic pipe as the "hammer" handle.

Give it a couple of good whacks and you're done. Bullet and brass separate, ready for reassignment. Have edited the above photo url's to forum size. with any luck they will show up |

|

@ 10:10 pm (GMT) |

Andrew MurrayRe: home made tumblerNice one Paul! |

Please wait

Please wait