Discussion Forums

Forum Index

> Rifles general discussion

> goats and 223

goats and 223

@ 11:11 pm (GMT) |

jonathan scottHi Nathan.Enjoyed the Reloaders videos online. They should have used a remote mic though, sometimes hard to hear. Ok, so I managed to pick up a "cheap" 223 from a mates mate for hares, bunnies and goats - it won't be used for reds but maybe chamois. It's a Brno ZKK601, with set trigger and has been rebarrelled with a 26inch heavy barrel and bedded. It needs a scope, so haven't shot it yet. Questions: 1. As I can't load, previously mentioned I don't have the kit or the house suitable, how do I go about picking a factory load to suit (a) hares and (b) goats. 2. How do I know if the previous owners bedding job and barrel are any good? Cheers |

Replies

@ 08:09 am (GMT) |

Nathan FosterRe: goats and 223Hi Jonathan, these are all very good questions.To check the bedding, remove the action screws and pull the action the from the stock. As you pull, check to see if it binds, does it come out smoothly or is it pinched and does it have to be rocked out. If it is pinched and the fit too tight, it may double group or simply produce wide groups. While apart, put some grease on the sides, bottom and front of the recoil lug, re-insert the action into the stock and check to see if these areas are contacting the bedding. If they are, the bedding will need to be relieved in this area, again, so that the sides, front and bottom of the lug have a minute amount of clearance. This will smooth up the fit, the sides of the action itself should be fine and non binding as you will note that the Brno workers have linished a taper onto the sides of the action. Re-assemble the rifle with the floor plate/ magazine spring in the open position, nip up the tang screw firmly, then, holding the rifle in the 1-Oclock position, tighten the front screw and check for any movement of the barrel up and down (in and out of the stock). If movement is evident, the bedding job will need to be re-don as the job is under stress. last checks include: make sure that the mag box is not pinched up against the action, it should be sloppy. If it has a fixed mag box where the metal is a part of the floor plate, there needs to be a .5mm gap- too much slop and the magazine won't feed, trapping projectile points at the gap at the front between the mag box and action. As a final check, Brno use the same front pillar system as M98 predecessor- incorporated into the floorplate assembly. Make sure that this front pillar is not touching the bottom of the recoil lug, it needs about 1mm gap. The online instructions for our bedding kits cover a lot of the finer details and these (including the pictures) can be used as a cross reference while you are making observations. Regarding the barrel, look into the chamber end and observe the throat, essentially, the tapered area of the lands. Look for and roughness (will look fuzzy or dull), There should be a somewhat crisp black shadow indicating that the taper is still in good form. As the throat wears right down, it will look long, of a very shallow angle and as suggested, dull or fuzzy. Look for any pitting etc. Once this is done, check the muzzle by looking into the muzzle from say a 45 degree angle, plenty of light. Look for machining marks, wear marks or stubborn fouling which may need addressing (see the barrel break in article in the knowledge base- can still be applied to an older or unknown bore). A magnifying glass can help a lot, the front bell of a Tasco or Nikko is ideal. Twist rate can be measured by indexing a tightly patched ram rod and measuring the distance of one full rotation. Belmont have some pretty good deals on ammo at the moment. As always, its a matter of trying different loads and finding what your rifle likes. Its a pity no one makes a load with the heavy A-Max bullets however, Belmont do furnish inexpensive 60 grain soft point loads that will work well on goats. http://www.belmontammunition.com/index.php?page=ammo&class=3&cat=.223 |

@ 08:06 pm (GMT) |

jonathan scottRe: goats and 223well I've been sitting on the rifle for a while. Finally got some money for a scope and needed to do some work on the gun. The un-set and set positions was breaking at 1lb - very scary. There were some other minor issues so I took it to Gunworks who came up tops with the work incl replacing the original scopemounts for something more modern. I also fitted a Burris Sig select BDC recticle I picked up for reasonable SH cost.

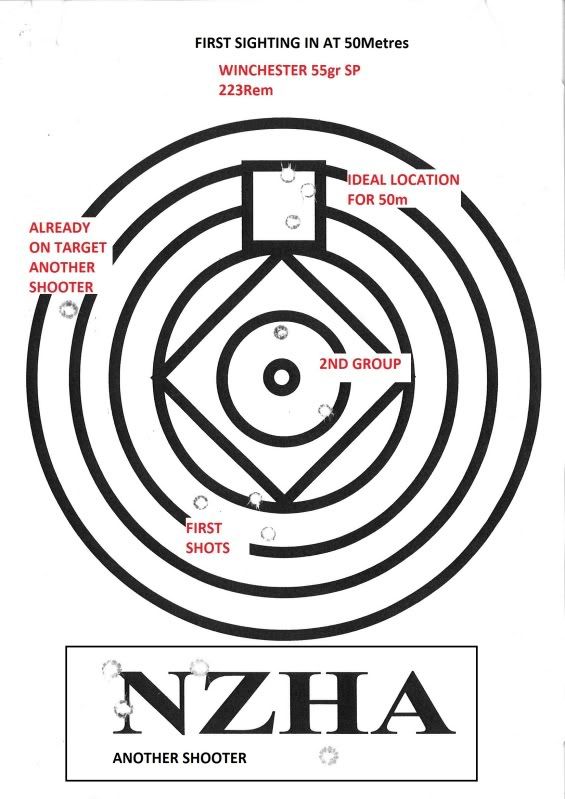

First shots at the range were interesting. I was constantly getting feed issues from 2nd and 4th rounds in the staggered magazine. So took my time after sighting to 50m. Here's the grouping. First setting up on the 50m range. A few floaters then got adjusted to bull and finally up a couple of inches to prepare for the 100m range.

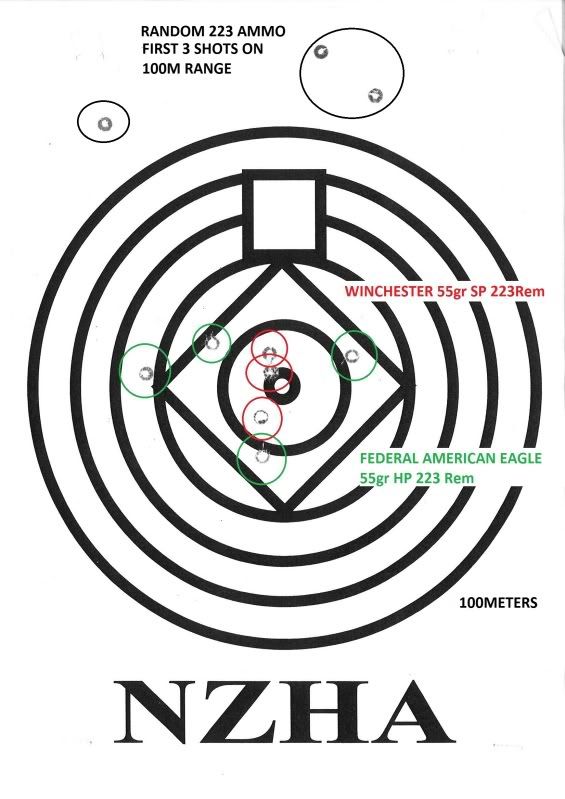

A couple of old rounds that came with the gun damaged from the feed issues went first. Then the federal and finally the winchester.

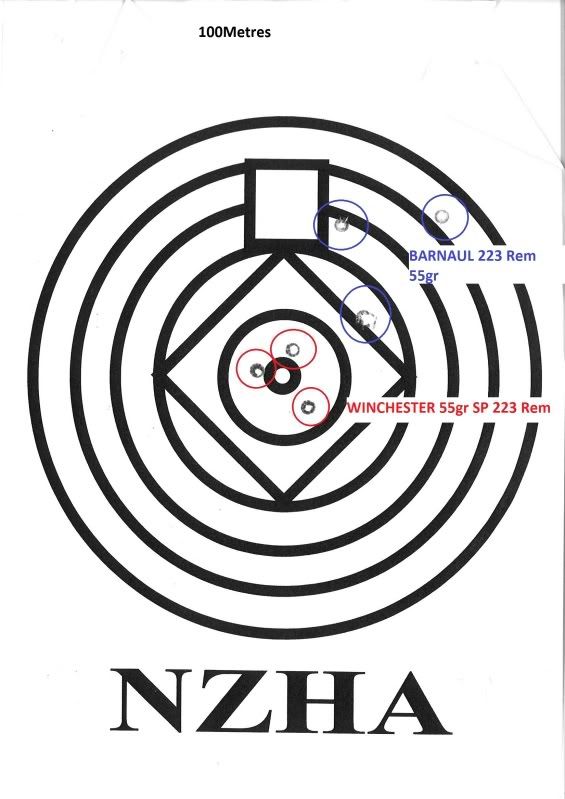

Lastly, some Barnaul ammo - crap. Switched to the winchester after tightening up the scope. Guess what I'll be buying.

|

@ 08:11 pm (GMT) |

jonathan scottRe: goats and 223Last night another Brno ZKK601 (in 308) owner called round and we looked at the feed issue. He had seen this on his rifle and found a modification on the web. Basically the mag follower was sliding around on the W shape spring steel, and the spring was moving on the mag trapdoor. So we put a little kink on either end and the added pressure locks both follower and plate to the spring. Hey presto. Good feeds for up to 4rds.However, it's a 6rd internal mag and if I load up to 6, the feeding is intermittant again. So I'm looking into this over the next few nights. I HAVE found that the front of the magazine follower is a bit rough, probably from the previous owner forcing the rounds home regardless, so I'll have to use some very fine wet n dry on that. The bolt being a Mauser style action runs a little tight about a 1/4 of the way in. I think it needs good lubrication. Is it ok to use PTFE dry lube along the bolt? How about the dovetails at the back of the receiver where the bolt engages? |

@ 09:56 am (GMT) |

Nathan FosterRe: goats and 223Hi Jonathan, its not uncommon for the CZ /Brno rifles to feed roughly due to the course finish left on the steel and as you found, poor fitting. These are after all, made to a budget.Besides the position of the follower and mag spring, the height of the action as it sits in the stock is critical in the Mauser designs. These are usually fitted very well at the factory, but the heights can become disturbed during bedding. If the actions sit too high, creating a large gap between the action and magazine box, the floor plate will jam between this gap. If on the other hand, the action sits too low and jams the magazine box in place, the rifle will be stressed in its bedding, resulting in extremely poor accuracy. The height of the Mauser type action as it sits in the stock is critical. The claw of the extractor can be polished for smoother engagement of the case head during feeding. This does however have to be done carefully to avoid weakening the tip of the extractor but is worth doing as it prevents jams caused by single fed rounds. Lubrication can be put on the bolt body but a 3:1 oil tends to be better than a dry lube as a means to prevent rust corrosion. The rear of the locking lugs should also be given a light coating of axle grease. The Mauser style actions can be sticky to feed (during the forwards motion of chambering) due to bolt slop within the action. This bolt slop was once critical in the M98 to prevent jams occuring via dust, mud or snow build up in the action. These actions feed smoothly when the heel of the palm is used, simply forcing the bolt forwards and home. If the actions are fed too slowly, the bolt can kick off at an angle and become jammed against the side walls of the action. It is possible to polish the internal surfaces of the action to minimize binding, however, it is not necessary. Once the design premise is understood, what was once seen as a flaw becomes recognized as deliberate. Methods of chambering and usage can then be altered accordingly. One factor I neglected to mention in the first reply, is that CZ/Brno use a 1:14 twist in their standard barrels, optimised for 50 grain projectiles. This is why it is important to test a variety of ammunition because, not all 55 grain bullets will stabilize in your barrel, more so for 60 grain projectiles. |

@ 04:18 pm (GMT) |

jonathan scottRe: goats and 223Thanks Nathan.I had a look at the the mag follower. On a 308 model it's a solid piece of machined steel, engraved 308 Win. On my 223, it's engraved 223 Rem but has an extra tip "welded" on which was really rough finished. I polished it a bit with 800 wet n dry and it's improved it, but still not feeding well every time. Basically 4rds in the mag are the limit, even though it holds 6. The barrel is an unmarked after market heavy barrel. I must try and find out the twist rate. However, it did the business alright last weekend. 2 Nannies up close, a couple of hares at 208 & 231 respectively. Then a Billy at 138m and a nanny beside him. I'd done a 200m stalk up under radio guidance from my buddy back down the other face, got into position and used my liteweight shooting sticks for solid rest. On impact he leapt up, took 4 steps and rolled down the hill. We took his head for a skull mount.

|

@ 05:18 pm (GMT) |

Nathan FosterRe: goats and 223Nice! Some good curries in those two young goats there. |

Please wait

Please wait